Coal dust and algae can help meet future energy needs

by Heather Dugmore, December 15 2015, 06:18, Business Day, BDLive

http://www.bdlive.co.za/business/innovation/2015/12/15/coal-dust-and-algae-can-help-meet-future-energy-needs

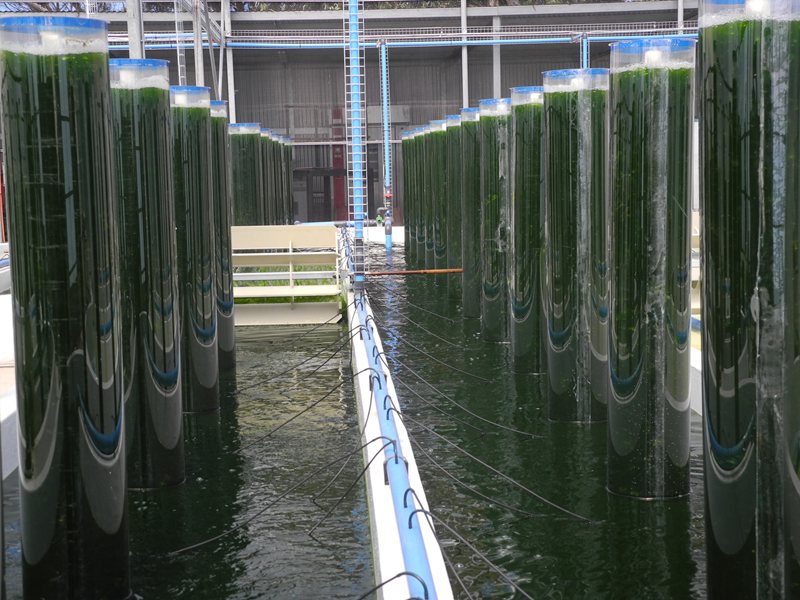

Coalgae is produced by growing algae in ponds stacked with bioreactors. The microalgae slurry is then mixed with coal dust and formed into briquettes.

A NEW fuel, Coalgae, produced from a combination of waste coal dust and algae, could save SA up to 40% of its crude oil imports.

Ben Zeelie and his team at Nelson Mandela Metropolitan University (NMMU) combined coal dust with algae to form neat, clean-burning briquettes. When heated up, they produce high-quality crude oil — an invention that is science at its best.

"The trigger that led us to Coalgae was completely accidental," says Prof Zeelie, who heads a research-and-development institute at NMMU in Port Elizabeth, called InnoVenton.

"We were experimenting with growing algae in plastic bags, when we noticed that some of it had leaked out the bags and formed a concentrated algae cake. It got us thinking and we figured that if we bind the algae cake with coal dust, we could come up with a new fuel."

They have produced a new product that is a breakthrough in clean-burning fuels.

Together with his team of academics, postgraduate and postdoctoral students, it has taken Prof Zeelie five years to perfect Coalgae, and to ensure they can produce it economically and at scale.

The team is conducting the final consistent production runs to confirm the economics of the product for take-off agreements. Organisations in the US, China, France and Indonesia are interested, and Prof Zeelie says that they are looking at an international licence.

...

PROF Zeelie is the personification of a brilliant inventor conducting fantastical experiments in his futuristic garden of bioreactors bubbling with green slime in a nondescript enclave on a university campus.

His discovery could turn around the coal mining industry’s 30% production loss in recent years, add a clean-burning fuel to the mix, reduce SA’s carbon footprint and reduce the country’s reliance on crude oil imports by about 40%.

"In coal mining you lose up to 30% of the coal as dust," Prof Zeelie explains. "The dust is conventionally a waste product that needs to be buried because otherwise the wind would blow it away. We’re not talking small amounts, we’re talking 50-million to 60-million tonnes of coal dust waste every year that needs to buried. This is both a huge economic loss and a huge environmental problem as it releases acid water and other chemicals into the soils over time."

The team discovered, after they started experimenting with algae cake and coal dust, that the algae binds beautifully with the dust. The bacteria in the algae are able to change the complex structure of coal.

They have succeeded in combining a waste product and a free product — common and garden South African algae — to produce an environmentally friendly fuel that does not require additional prospecting, mining or blasting.

...

THEY grow the algae fast in vast, shallow artificial ponds stacked with bioreactors to produce microalgae slurry. This is then pumped into settling ponds to produce an algae concentrate that is then mixed with the coal dust waste, and compressed into neat briquettes, which are dried.

"When we heat up the Coalgae briquettes to about 450°C in the absence of oxygen, we are able to produce a high-quality crude oil and a solid, clean-burning fuel.

"When we burn the Coalgae, it burns without smoke — the combustion behaviour is totally different to burning coal. The oil can be processed in a normal oil refinery, while the solid fuel can be used as thermal coal for heat and energy generation. Hence, if we were to convert the 50-million to 60-million tonnes of coal dust waste into Coalgae and heat it, we could produce over 40% of SA’s crude oil needs, and similar impressive percentage in other coal-producing countries."

Prof Zeelie says it makes the most economic sense to use the full Coalgae production for crude oil. "It is a very high-quality oil, like Texan sweet crude, rich in gasoline and aviation fuel components. The price would be more or less the same, but the market would be stable, with significant environmental benefits."

Inventors and the university will receive some of the income from licensing agreements, which would help them to upscale InnoVenton’s capacity to produce more inventions.

"Our goal at InnoVenton is to draw on top science in SA to aid industry and improve products and processes worldwide," says Prof Zeelie. "That is why I am lying awake at night," he says with a smile.

When heated up to about 450oC the briquettes produce a high-quality crude oil and a solid, clean-burning fuel.